No shortcuts to controlling Salmonella

There are no shortcuts to controlling the existence and impact of Salmonella in the poultry industry, just a massive amount of hard work and attention to detail, from chick production right through to the finished bird.

Effective biosecurity starts with the creation of farms which are designed to keep germs out and continues throughout a breeding-to-finishing cycle which is protected from the introduction of new pathogens at all points. Equipping the birds themselves to withstand salmonella attacks also has a major part to play in maintaining the industry's defences against this highly damaging condition.

Salmonella contaminations are associated with 90 million diarrhea-based infections each year, making it the most common bacterial zoonotic disease in the world, according to its official rating in the USA.

While many foods are associated with Salmonella outbreaks, the poultry industry is acknowledged as the main animal-to-human transmission vector, being responsible for 29% of global cases, through poultry meat, and 18%, through eggs.

The challenge to combat Salmonella within the poultry industry has massive global importance, therefore, demanding firm and urgent action to raise biosecurity measures to ever-improving levels of efficiency and effectiveness.

The first step is to address the physical structure and organisation of farms by blocking all possible entry routes for germs to work their way into vital production areas.

Priority action, in this context, includes restricting the number of people allowed to enter the farm to an absolute minimum. The farm staff themselves obviously need access, plus veterinary support when on-sight treatment is necessary. Specialist technicians will also be needed to carry out essential maintenance tasks or deal with equipment failure. Apart from that, the farm gate should remain closed.

Even for such limited numbers of approved staff and visitors, farms should have an entry process in place to prevent germs from being introduced into production areas. Some farms already use a three-stage entry system, requiring visitors to change their clothes, wash and put on clear farm clothing before working in poultry areas.

Other standard tasks, such as delivering feed to a farm, also need a secure entry and unloading process which keeps the vehicle isolated at all times, preventing any farm-to-farm contamination.

Stopping wild birds, insects and rodents from bringing infections into production areas is another major challenge. Solutions include fitting grills to air entries to keep wild birds out and clearing plants and weeds from the areas surrounding poultry houses to remove habitat options for insects and rodents.

The selection of easy-to-clean building materials is also important, ideally resulting in smooth walls and concrete floors inside, and concrete slabs outside, all of which can be washed and disinfected regularly.

Maintaining high-health standards for the birds themselves is equally vital, a management rule which needs to run from breeders and their provision of day-old chicks through to broiler and layer houses. An obvious pre-requisite for producers is that all new stock should be clear of infection when they enter the production process, creating a high-health foundation to be maintained thereafter.

Working against such a background, research trials have demonstrated that feeding the yeast fraction Safmannan® as a dietary supplement to birds, is an effective nutritional boost to their health and performance. Findings show that the supplement helps reduce Salmonella shedding by birds as a result of binding gram (-) bacteria, strengthening their gut barrier and stimulating their immune system, making them more able to fight off dangerous pathogens.

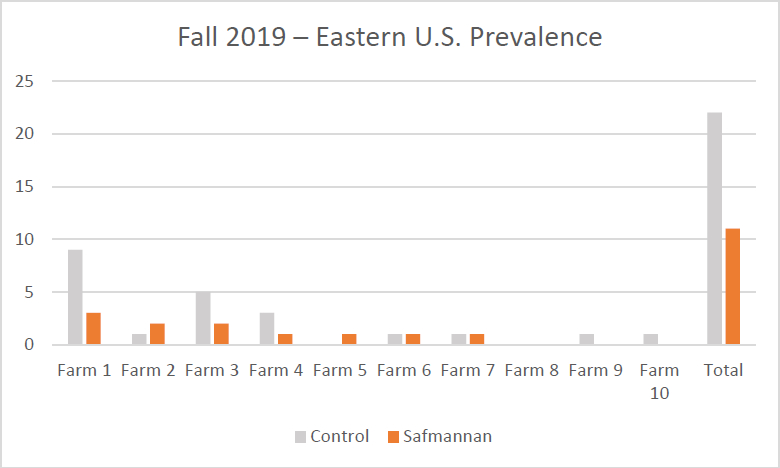

For example, supplementing Ross 708 birds with Safmannan® across several farms in a Southern US trial last year, delivered a 50% reduction in the prevalence of Salmonella.

A trial with layers (P.T. Price et al.) showed Salmonella Enteritidis in the ceca running at 58% in a control group of birds but only 17% in those receiving Safmannan®. The supplement also reduced the number of Salmonella Typhimurium in the ceca between the control group's 4.71 rating and the Safmannan® group's level of 3.41.

Similarly, a breeding stock trial (Zhou et al., 2019) showed significant reductions in the prevalence of Salmonella Pullorum and Salmonella Gallinarum in birds supplemented with Safmannan®, compared with a non-supplemented control group.

Trials with broilers (Kiros et al., 2018), meanwhile, showed Safmannan® delivering significantly reduced numbers of Salmonella Heidelberg in supplemented birds during the growth period to day 42, while a US field trial in 2018 recorded a reduction, within one unit, from a Salmonella prevalence of 25% in control birds to zero in those given Safmannan® as part of their diet.

With Salmonella currently associated with 91,000 foodborne infections a year in Europe, the poultry industry's need to keep working to control on-farm infections remains a high-priority challenge for farmers and everyone else in the sector.

For more of the article, please click here.